Editor’s note: A few years ago, some of our team took a cheese tour of Italy. One of our team members, Andrew Perlgut, wrote about the experience, and we are re-publishing his post from September, 2015.

My journey to the Italian countryside, somewhere between Reggio Emilia and Parma, began 4 years ago—before any of the aging, gorgeous wheels of Parmigiano Reggiano had begun their life as milk, before the cows had eaten the lush grasses growing nearby, before Riccio and his team heated the milk, added the rennet and salt, cut the curds, formed the wheels, and then brined them. My journey began before all of that, in a dimly lit conference room upstairs at Murray’s HQ, with a dozen of my coworkers.

On that afternoon four years ago, as we filed into the room, over thirty different plates of Parmigiano-Reggiano were arrayed across the room. We were given simple instructions: pick the best one.

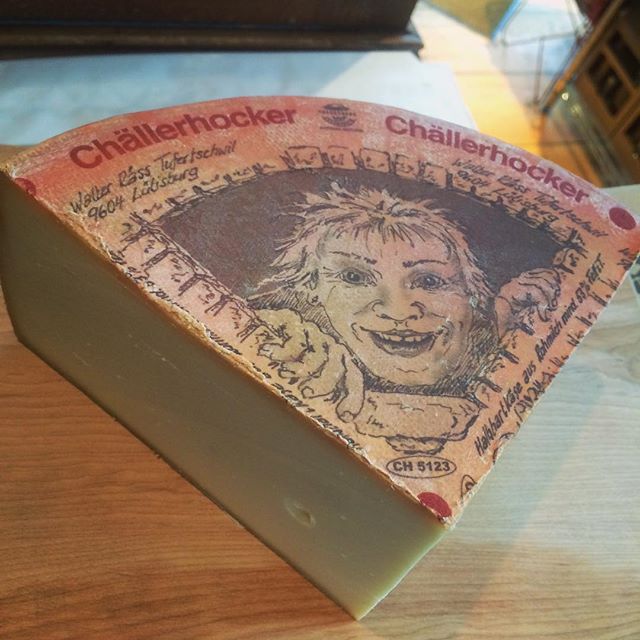

Parmigiano-Reggiano, the King of Cheese, is PDO, or protected designation of origin. That means that, to make it, you must follow a strictly codified recipe and live within a very specific geographic area.

With aged cheeses, the goal is to get as much moisture out of the curds as possible, so that there is no spoilage during the aging process. Removing moisture is a multistep process, involving salting, heating, and cutting the curds. The salt works through osmosis, pulling liquid out of the curds while introducing sodium back into them. The heat causes evaporation. Cutting the curds smaller and smaller removes any pockets in which moisture might hide in.

Parmigiano-Reggiano starts by combining skimmed milk from the previous evening with whole milk from the morning’s milking. From there, the new, partially-skimmed milk gets pumped into giant copper vats. The vats are heated, rennet is added, and the milk begins to separate into curds and whey. The curds are then cut, the vat is heated again, and the curds are hooped together. No cheesemaker who produces PDO Parmigiano-Reggiano can deviate from this process in the slightest, which is what guarantees that remarkable consistency you notice from one piece of Parmigiano-Reggiano to the next.

So, if all parm should taste the same, why did we go through that tasting exercise 4 years ago? Because, while the PDO helps to guarantee that the cheese you are getting conforms to certain requirements, there are other factors at play in the cheesemaking process: the specific feed of the cows, minuscule variations in temperature and time between cheesemakers, the length and conditions of the aging process, where the cows happen to be in the reproductive cycle, etc. All of these pieces, when put together, can lead to noticeable differences. So we tasted through the 30 different options, and we narrowed them down.

And then a few months later we did it again.

By repeating the tasting, we got to try wheels from different parts of the year and with slightly different ages. We tasted wheels that tended toward the nuttier side, we tasted wheels that were overwhelmingly fruity, and, if my tasting notes are to be believed, we tasted wheels that had a distinctly broccoli-ish flavor.

Each subsequent tasting helped narrow down the options until we ultimately determined a favorite. It had the perfect balance of nutty and fruity, salty and sweet, savory and umami. Then we reached out to the farm that produced it, locked in their entire production, and officially had what you now know as Murray’s Parmigiano-Reggiano.

For a cheesemonger, the first time you crack open a wheel of Parmigiano-Reggiano is always a memorable experience. I remember my first perfectly. I was helping to train some new cheesemongers in Cincinnati and was told to show them how to crack open parm. No problem! The most beautiful thing about cracking a wheel of parm is this: milk, at most 16 hours old, goes through the cheesemaking process, and once that wheel is put into its mold, the milk on the inside begins a two-year residency on a shelf. When a cheesemonger cracks a wheel, that milk is seeing the light of day for the first time in over 730 days.

Four years on, I finally got to walk into the making room where our Parm is crafted. I’ve cracked many wheels of Parm, but this was going to be my first time seeing that milk in liquid form.

The first room we walked into, the cheesemaking room, was hot and humid and bustling with activity. We walked through it and into the refrigerated milk room, where the milk comes in each evening to sit and await the next morning’s milk.

Back into the humidity and heat, and we got to meet Riccio and watch him and his team make Parmigiano-Reggiano. The walked us through the whole process as they went, from heating up the milk and adding the rennet to cutting, gathering, and pressing the curds.

After settling into their final shapes, the wheels take a 20-day bath in a salt brine to help further reduce internal moisture and bring the saltiness of the cheese up to the levels that we know and love.

And then, they wait. For two whole years. We can call this their growing up phase, when they are reaching a point of being mature enough to assume the throne as the King of Cheese.